Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

The Unsung Hero: The Role of Copper Gaskets in Caterpillar Automobile Engines

When we think about automobiles, our minds often race to sleek designs, powerful engines, and cutting-edge technology. However, amidst the roar of the engine and the gleam of the exterior, there exists a humble yet indispensable component that plays a crucial role in ensuring the smooth operation of vehicles – the copper gasket.

Copper gaskets may not grab headlines or steal the spotlight, but within the intricate machinery of Caterpillar automobile engines, they serve as silent heroes, sealing critical junctions and preventing leaks that could jeopardize performance. Let's delve deeper into the significance of these unassuming components and their impact on the functionality of Caterpillar engines.

The Backbone of Reliability:

Caterpillar engines are renowned for their robustness and reliability, capable of powering heavy-duty machinery across diverse industries. Behind this reputation lies meticulous engineering and attention to detail, with every component meticulously designed to withstand extreme conditions and prolonged use. Copper gaskets emerge as integral components, forming a tight seal between engine parts to prevent leakage of fluids or gases under high pressure and temperature.

Precision Manufacturing:

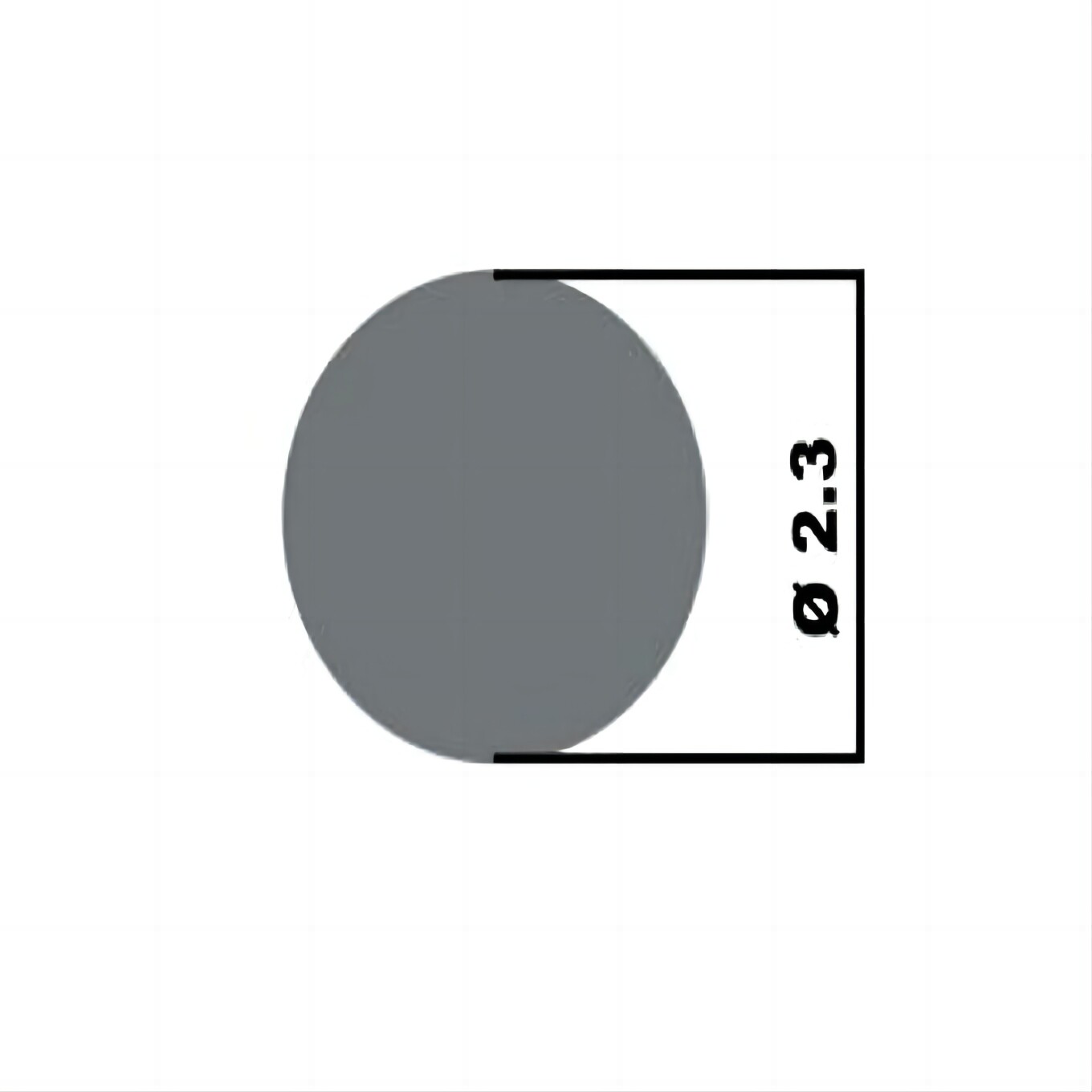

The journey of a copper gasket from raw material to finished product involves precision manufacturing processes that ensure optimal performance. Specialized manufacturers employ advanced techniques to craft gaskets with the exact dimensions and specifications required for Caterpillar engines. Each gasket undergoes rigorous quality checks to guarantee durability and resilience under demanding operating conditions.

Sealing the Deal:

At the heart of every Caterpillar engine lies the combustion chamber, where the controlled explosion of fuel and air drives the vehicle forward. The integrity of this chamber is paramount, and copper gaskets play a pivotal role in maintaining it. By forming a tight seal between the cylinder head and engine block, copper gaskets prevent leakage of combustion gases, ensuring maximum power output and fuel efficiency.

Heat Resistance and Durability:

Caterpillar engines operate under extreme conditions, subjected to intense heat and pressure as they power heavy machinery through rugged terrain. Copper gaskets excel in this environment, thanks to their exceptional heat resistance and durability. Unlike conventional gasket materials, such as rubber or paper, copper can withstand high temperatures without deforming or losing its sealing properties, ensuring long-term reliability and performance.

Adaptability and Innovation:

As technology evolves and engine designs become more sophisticated, the demand for advanced gasket solutions grows. Manufacturers continually innovate, developing specialized gaskets tailored to meet the specific requirements of modern Caterpillar engines. From multi-layered designs to coatings that enhance sealing efficiency, these innovations underscore the adaptability of copper gaskets in an ever-changing automotive landscape.

Conclusion:

In the intricate ecosystem of Caterpillar automobile engines, copper gaskets emerge as unsung heroes, quietly ensuring the smooth operation and reliability of these powerful machines. From their precision manufacturing to their crucial role in sealing critical junctions, copper gaskets embody the marriage of craftsmanship and functionality. As automotive technology continues to advance, the humble copper gasket will remain a vital component, steadfastly supporting the performance and longevity of Caterpillar engines. So, the next time you marvel at the power and precision of a Caterpillar vehicle, spare a thought for the unsung hero – the copper gasket – silently sealing the deal beneath the hood.