Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

OEM Caterpillar Valve Modules Copper Gasket: What You Need to Know

When it comes to heavy machinery and diesel engines, every component, no matter how small, plays a crucial role in ensuring optimal performance. One such component that often goes unnoticed but is vital for sealing and preventing leaks is the copper gasket found in OEM Caterpillar valve modules. But what exactly is this copper gasket, and why is it so important? Let's dive into the world of OEM Caterpillar valve modules copper gaskets to unravel the mystery.

What is a Copper Gasket?

Understanding Gaskets

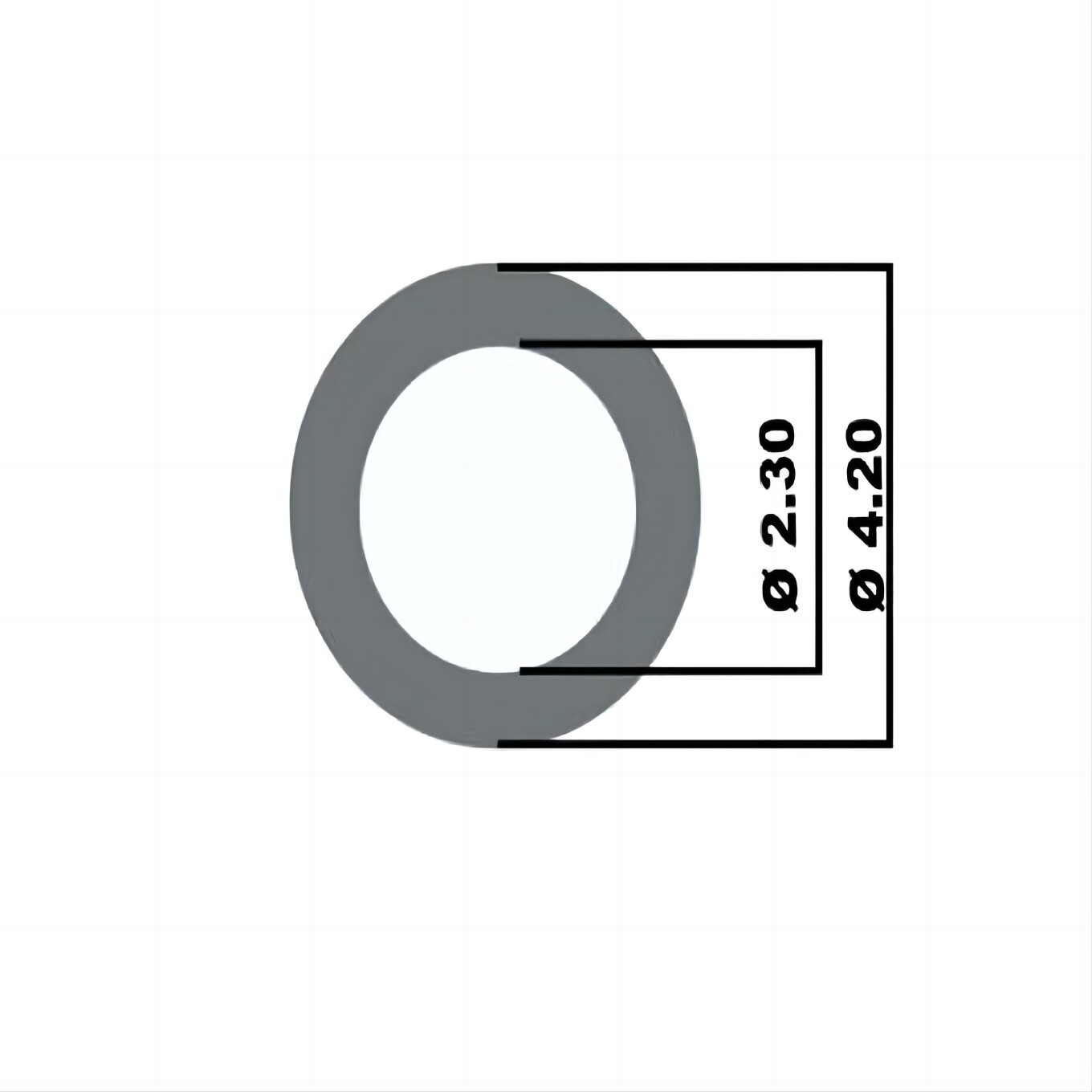

A gasket is a mechanical seal that fills the space between two mating surfaces, generally to prevent leakage from or into the joined objects while under compression. In the context of OEM Caterpillar valve modules, the copper gasket serves as a sealing solution to ensure a tight and leak-free connection between the valve module and other engine components.

Why Copper?

Copper is often chosen for gaskets due to its excellent thermal conductivity, malleability, and corrosion resistance. These properties make copper an ideal material for gaskets in high-temperature and high-pressure applications like diesel engines.

The Role of Copper Gaskets in OEM Caterpillar Valve Modules

Sealing Function

The primary role of the copper gasket in OEM Caterpillar valve modules is to provide a reliable seal between the valve module and other engine components. This ensures that no fuel or exhaust gases leak out, maintaining optimal engine performance and efficiency.

Heat Resistance

Diesel engines, especially those in heavy machinery, operate at high temperatures. The copper gasket's heat resistance ensures that it can withstand these extreme temperatures without deforming or losing its sealing properties.

Corrosion Resistance

In addition to heat resistance, the copper gasket's corrosion resistance ensures that it remains intact and effective even in harsh operating conditions, prolonging its lifespan and reliability.

Benefits of OEM Caterpillar Copper Gaskets

Superior Sealing Performance

OEM Caterpillar copper gaskets are designed and manufactured to meet Caterpillar's stringent quality standards. Their precise design and high-quality materials ensure superior sealing performance, preventing leaks and maintaining engine integrity.

Longevity and Durability

Thanks to their high-quality copper construction and excellent heat and corrosion resistance, OEM Caterpillar copper gaskets offer long-term durability and reliability, reducing the need for frequent replacements and maintenance.

Compatibility

OEM Caterpillar copper gaskets are designed to fit perfectly with Caterpillar valve modules, ensuring a seamless integration and optimal performance. This compatibility eliminates the risk of leaks and ensures a tight seal, even under extreme conditions.

Maintenance Tips for OEM Caterpillar Copper Gaskets

Regular Inspection

Regular inspection of your OEM Caterpillar copper gaskets is crucial for maintaining optimal performance. Look out for signs of wear and tear, such as leaks or corrosion, and address any issues promptly to prevent further damage to your engine.

Proper Installation

Proper installation of OEM Caterpillar copper gaskets is essential to ensure optimal sealing performance. Always follow Caterpillar's installation guidelines and use the recommended tools and techniques to install the gaskets correctly.

Professional Servicing

While basic maintenance can be done at home, it's always a good idea to have your Caterpillar engine professionally serviced by a qualified technician. They have the expertise and tools to diagnose and fix any issues that may arise, ensuring your engine performs at its best for years to come.

Conclusion

OEM Caterpillar copper gaskets play a vital role in ensuring optimal performance, efficiency, and reliability of Caterpillar engines. Their superior sealing performance, durability, and compatibility make them an essential component for any Caterpillar engine.

By understanding the importance of copper gaskets in OEM Caterpillar valve modules and following the maintenance tips mentioned above, you can ensure that your engine remains leak-free, efficient, and reliable for years to come.

So, the next time you're working on your Caterpillar engine or replacing components, remember the importance of the copper gasket in ensuring a tight seal and preventing leaks. With its crucial role in engine performance, the copper gasket truly is a small but mighty component that deserves recognition and care!