Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

OEM caterpillar fuel diesel injector nozzle parts

Caterpillar Fuel Injector Nozzle Parts

Description: Caterpillar fuel injector nozzle parts are essential components of Caterpillar diesel engines, responsible for precisely delivering fuel into the combustion chamber for efficient combustion. These parts are meticulously engineered and manufactured to Caterpillar's stringent quality standards, ensuring optimal engine performance, fuel efficiency, and emissions control. Caterpillar offers a comprehensive range of fuel injector nozzle parts designed to meet the specific requirements of various engine models and applications.

Parts:

- Injector Nozzle Body: The main housing of the fuel injector nozzle, which contains the internal components and directs the fuel spray into the combustion chamber.

- Injector Nozzle Tip: The nozzle tip is the component that atomizes the fuel and directs it into the combustion chamber. It is engineered for precise fuel delivery and optimal spray pattern.

- Needle Valve: The needle valve controls the flow of fuel through the injector nozzle, regulating the fuel delivery according to engine operating conditions.

- Spray Holes: These are small openings on the injector nozzle tip through which the pressurized fuel is sprayed into the combustion chamber. The size and shape of the spray holes influence the fuel spray pattern and combustion efficiency.

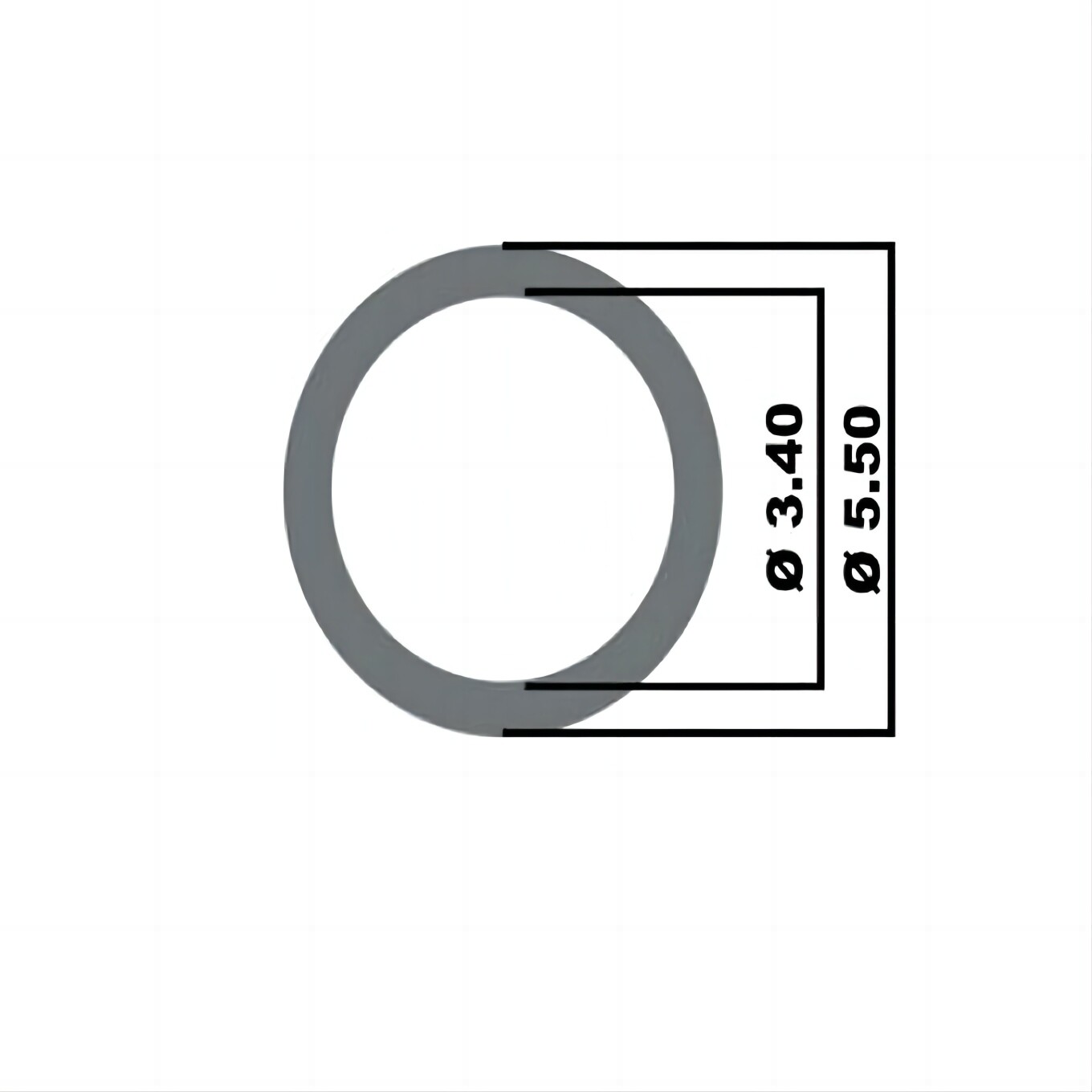

- Sealing Washer: The sealing washer ensures a tight and leak-free seal between the injector nozzle and the fuel injection system, preventing fuel leakage and maintaining system integrity.

- Fuel Inlet Fitting: The fuel inlet fitting connects the injector nozzle to the fuel supply line, allowing fuel to enter the injector for injection into the combustion chamber.

- O-rings: O-rings provide sealing and prevent fuel leakage between mating components, such as the injector nozzle body and the cylinder head.

Features:

- Precision Engineering: Caterpillar fuel injector nozzle parts are precision-engineered to exacting tolerances for reliable performance and durability.

- Quality Materials: Made from high-quality materials that withstand the rigors of engine operation, including heat, pressure, and chemical exposure.

- Optimized Performance: Designed to optimize fuel delivery, combustion efficiency, and engine power output while minimizing emissions and fuel consumption.

- Compatibility: Caterpillar offers a wide range of injector nozzle parts designed to fit specific engine models and applications, ensuring compatibility and ease of installation.

- Longevity: These parts are built to withstand the demanding operating conditions of Caterpillar diesel engines, providing long-lasting performance and reliability.

Applications:

- Heavy Equipment: Used in Caterpillar diesel engines powering a wide range of heavy equipment, including bulldozers, excavators, loaders, and dump trucks.

- Industrial Applications: Caterpillar fuel injector nozzle parts are also used in stationary and industrial diesel engines used in power generation, mining, marine, and other industrial applications.

Maintenance and Replacement:

- Regular inspection and maintenance of fuel injector nozzle parts are essential to ensure optimal engine performance and reliability.

- Replace worn or damaged injector nozzle parts promptly to prevent fuel leakage, poor engine performance, and potential damage to the engine.

Caterpillar fuel injector nozzle parts play a crucial role in the performance and reliability of Caterpillar diesel engines, providing precise fuel delivery for efficient combustion and optimal engine operation. With their quality construction, precision engineering, and compatibility with Caterpillar engine models, these parts are trusted by operators and technicians worldwide to keep Caterpillar-powered equipment running smoothly and efficiently.

Caterpillar Diesel Injector Nozzle Parts

Description: Caterpillar diesel injector nozzle parts are vital components of Caterpillar diesel engines, responsible for delivering precise amounts of fuel into the combustion chamber for efficient combustion. These parts are meticulously engineered and manufactured to Caterpillar's exacting standards, ensuring optimal engine performance, fuel efficiency, and emissions control. Caterpillar offers a comprehensive range of diesel injector nozzle parts designed to meet the specific requirements of various engine models and applications.

Parts:

- Injector Nozzle Body: The main housing of the diesel injector nozzle, containing internal components such as the nozzle tip and needle valve.

- Nozzle Tip: The nozzle tip is responsible for atomizing the fuel and directing it into the combustion chamber. It is engineered for precise fuel delivery and optimal spray pattern.

- Needle Valve: The needle valve controls the flow of fuel through the injector nozzle, regulating the fuel delivery according to engine operating conditions.

- Spray Holes: These small openings on the nozzle tip allow pressurized fuel to be sprayed into the combustion chamber. The size and shape of the spray holes influence the fuel spray pattern and combustion efficiency.

- Sealing Washer: The sealing washer ensures a tight and leak-free seal between the injector nozzle and the fuel injection system, preventing fuel leakage and maintaining system integrity.

- Fuel Inlet Fitting: The fuel inlet fitting connects the injector nozzle to the fuel supply line, allowing fuel to enter the injector for injection into the combustion chamber.

- O-rings: O-rings provide sealing and prevent fuel leakage between mating components, such as the injector nozzle body and the cylinder head.

Features:

- Precision Engineering: Caterpillar diesel injector nozzle parts are precision-engineered to exacting tolerances for reliable performance and durability.

- Quality Materials: Made from high-quality materials that withstand the harsh operating conditions of diesel engines, including heat, pressure, and chemical exposure.

- Optimized Performance: Designed to optimize fuel delivery, combustion efficiency, and engine power output while minimizing emissions and fuel consumption.

- Compatibility: Caterpillar offers a wide range of injector nozzle parts designed to fit specific engine models and applications, ensuring compatibility and ease of installation.

- Longevity: These parts are built to withstand the demanding operating conditions of Caterpillar diesel engines, providing long-lasting performance and reliability.

Applications:

- Heavy Equipment: Used in Caterpillar diesel engines powering a wide range of heavy equipment, including bulldozers, excavators, loaders, and dump trucks.

- Industrial Applications: Caterpillar diesel injector nozzle parts are also used in stationary and industrial diesel engines used in power generation, mining, marine, and other industrial applications.

Maintenance and Replacement:

- Regular inspection and maintenance of diesel injector nozzle parts are essential to ensure optimal engine performance and reliability.

- Replace worn or damaged injector nozzle parts promptly to prevent fuel leakage, poor engine performance, and potential damage to the engine.

Caterpillar diesel injector nozzle parts play a crucial role in the performance and reliability of Caterpillar diesel engines, providing precise fuel delivery for efficient combustion and optimal engine operation. With their quality construction, precision engineering, and compatibility with Caterpillar engine models, these parts are trusted by operators and technicians worldwide to keep Caterpillar-powered equipment running smoothly and efficiently.